| Publication number | US986695 A |

| Publication type | Grant |

| Publication date | 14 Mar 1911 |

| Filing date | 16 Mar 1909 |

| Priority date | 16 Mar 1909 |

| Inventors | Frank R Cunningham |

| Original Assignee | Kendrick And Davis Company |

| Referenced by (1), Classifications (1) | |

| External Links: USPTO, USPTO Assignment, Espacene | |

MAINSPRING WINDER APPLICATION FILED 11113.16, 1909.

PatentewMar. 14, 1911.

UNITED STATES PATENT OFFICE.

FRANK R. CUNNINGHAM, OF MEDFORD, MASSACHUSETTS, ASSIGNOR, BY MESNE AS- SIGNMENTS, TO KENDRICK AND DAVIS COMPANY, OF LEBANON, NEW HAMPSHIRE,

A CORPORATION OF NEW HAMPSHIRE.

MAINSPRING-WINDER.

To all whom it may concern:

Be it known that I, FRANK R. CUNNING- HAM, of Medford, in the county of Middlesex and State of Massachusetts, have invented certain new and useful Improvements in lvlainspring-VVinders, of which the following is a specification.

This invention relates to instruments for coiling or winding up main-springs for time-pieces, and its object is to make one instrument adaptable for coiling springs of a wide range of sizes.

Main-spring winders of the type to which the invention refers have an arbor rotatable in bearings, and provided with a hook or pin to engage one end of the springs. One of the bearings ,is provided with a flange for confining the spring as it is wound, and constituting a barrel. WVhen dilferent sizes of springs are to be wound, the barrels and arbors are removed and others suitable for the springs to be operated upon are substituted.

The particular improvement which constitutes the present invention is one which permits the arbor to be more readily removed from and replaced in its bearings. It is movable endwise readily into and out of one of the bearings, but cannot be so inserted in and removed from the other hear ing, on account of a collar and a crank formed on the arbor 011 opposite sides of the latter bearing. By this invention I have modified and improved such bearing so that the arbor may be readily slipped laterally into and out of the same, and may be locked therein against accidental displacement.

In the drawings I have illustrated the preferred embodiment of the invention.

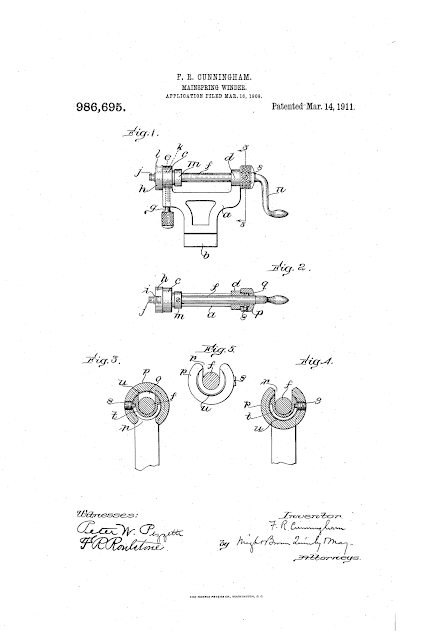

Figure 1 represents an elevation thereof. Fig. 2 represents a plan, showing the improved bearing constituting the invention, in horizontal section. Fig. 3 represents a section on line 33 of Fig. 1. Fig. 4L repre sents a section on the same line, showing the bearing lock in a different position. Fig. 5 represents an elevation of the locking sleeve for the bearing.

The same reference characters indicate the same parts in all the figures.

The winder itself consists of a frame or bracket 64 which is adapted to be held by its lower end Z) in a vise, or otherwise secured Specification of Letters Patent.

Application filed March 16,

in upright position. The frame has two Patented Mar. 14, 1911.

1909. Serial No. 483,763.

arms c and (Z, the former of which contains a sleeve 6, and the latter of which is itself a bearing for the winding arbor f. The sleeve 0 is retained in the frame 0 by a setscrew 9, and has on the outer end a cylindrical flange or barrel h provided with a notch 2′ through which the spring is drawn in being wound. On the end of the arbor is a pin or hook j, which engages with the inner end of the main spring, and coils the latter on the arbor, drawing it into the barrel through the notch 2″. Vithin the sleeve 0 is an endwise movable sleeve is which serves as the bearing for the end of the arbor, and into which this end is readily movable. A disk Z on the last-named sleeve is contained within the barrel h, and may be moved outward by a collar m on the arbor when the latter is pressed against the inner end of the sleeve, to push the wound-up main-spring from the barrel 7L and place it in the main-spring barrel of a watch. A crank it formed on the end of the arbor enables the latter to be rotated for winding springs.

The part of the device above described is no different from the standard spring winder which has long been on the market and is substantially the same in essential respects as the device illustrated, for example, in the patent to A. F. Robbins, No. 325,973, granted September 8, 1885, and I make no claim to the same as a part of my invention. The feature in which my invention consists is that which permits a ready removal and substitution of different arbors for the pur pose of permitting springs of different sizes to be wound, the essentials and the preferred form of construction of which appear from the remainder of this specification.

When springs of different sizes are to be wound, provision is made by removing and substituting diflerent arbors and bearing sleeves having barrel flanges of appropriate sizes. In order to permit ready removal and replacement of arbors, I have constructed the bearing (Z with a lateral opening or slot 0 of a width at least as great as the diameter of the arbor, so that the latter may be inserted and removed transversely of its axis. The arbor is held against accidental displacement by a locking sleeve or ring 9 journaled upon a hub q of the arbor, which sleeve or ring extends over the end of the hub and has an internal cylindrical surface forming a continuation of the surface of the bearing. This ring is incomplete, having an opening or slot ‘7″ in one side, of approximately the same width as the slot 0. The rotary mounting of the sleeve enables it to be turned so that the slot 1″ comes into registry with the slot 0, and in that position the arbors may be removed and inserted. Then shifted into another position, as shown inFig. 8, the ring extends across’ and obstructs the opening 0 so that the arbor cannot be removed. The ring is held in place by a stud preferably constructed as a set-screw s, which enters a groove in the hub g. A bow spring u is contained in the ring, being held in place by the screw 8′. This spring is curved on a slightly larger radius than the recess Within the ring in which it is contained, so that it bears at its ends against the walls of this recess andis slightly separated therefrom at its center when inequilibrium. On account of this construction, it exerts a frictlonal pressure against the huh by wh1ch 1t 1s kept from turning. too readily.

1. In a main-spring winder, a frame having a pair of arms, bearings in said arms, a winding arbor revolubly contained in said bearings, one. of the bearings having a hub I and a lateral opening, and a retaining ring journaled externally on said hub and hav ing a slot in its side.

7 2. In a main-spring winder, a frame having a pair of arms, bearings 1n sald arms, a winding arbor revolubly contained n said bearings, one of the bearings having a hub the ring is seated.

ent radius than that of the recess to exert a frictional pressure on the bearing whereou 4. In a tool of the character described, a locking ring having a central recess, and a bow spring in said recess bearing at its ends on, and separated between its ends from,

– the adjacent wall of the recess to press frictionally upon the hub whereon sald ring is seated.

5. In a main-spring winder, a frame having a pair of arms, bearings in said arms, a winding arbor revolubly contained in said bearings, one of the bearings having a hub and a lateral opening, a retaining ringjournaled on said hub and having a slot in its side, a stud set in said ring and entering a semicircumferentia1 groove in said hub to retain the ring thereon while permitting its rotary movement, and a spring contained in said ring between the adjacent surfaces of the spring and hub, bearing frictionally against the latter, and retained in place by said stud.

6. In a main-spring winder, a frame having a pair of arms, bearings in said arms, a

winding arbor revolubly contained in said bearings, one of the bearings having a hub and a lateral opening, a retaining ring journaled on said hub and having a slot in its side, a stud set in said ring and entering a semicircumferential groove in said hub to retain the ring thereon while permitting its rotary movement, and a spring contained in said ring between the adjacent surfaces of the spring and hub, bearing frictionally against the latter, and having an aperture through which said stud passes, whereby it is held in place.

In testimony whereof I have aflixed my signature, in presence of two witnesses.

FRANK R. CUNNINGHAM. IVitnesses P. W. PnzzETrI, E. BATGHELDER.

‘ Copies of this patent may be obtained for five cents each, by addressing the Commissioner of Patents,

‘ Washington, D. G.