| Publication number | US984354 A |

| Publication type | Grant |

| Publication date | Feb 14, 1911 |

| Filing date | Oct 23, 1907 |

| Priority date | Oct 23, 1907 |

| Inventors | Frank R Cunningham |

| Original Assignee | Kendrick & Davis |

| Referenced by (3), Classifications (1) | |

| External Links: USPTO, USPTO Assignment, Espacenet | |

POISING GALIPBRS.

APPLICATION FILED 00123, 19o?.

Patented Feb. 14,1911.

ces es afm@ @au L e.

1u: Noam; grans ca, wArrmNcroN, n. c

UNITED PATENT OFFICE.

FRANK R. CUNNINGHAM, OF MEDFORD, MASSACHUSETTS, ASSIGNOR TO KENDRICK 6c DAVIS, OF LEBANON, NEW HAMPSHIRE, A FIRM.

. ,.1 POISING-CALIPERS.

Application filed October 23, 1907.

To. all whom it may concern:

Be it known that l, FRANK R. CUNNING- HAM, of Medt’ord, in the county oi’ Middlesex and State o’t Massachusetts, have invented certain new and useful Improvements in Poising-Calipers, o’tl which the following is a specification.

The present invention consists in a tool for holding balance wheels oi’ watch or clock movements while being poised.

The objects are to provide a tool of this character permitting more rapid insertion and removal of work than in the poising tools heretol’ore used, lto permit an accurate adjustment ot’ the bearings tor the stattl ot’ ay balance wheel, to hold the same without looseness and also without end pressure, to provide a novel form of jewel bearing t’or the ends et’ a statt constructed with two jewels made separable so that they may be cleaned, and to provide other improved details oit’ construction which will be hereinafter more particularly described.

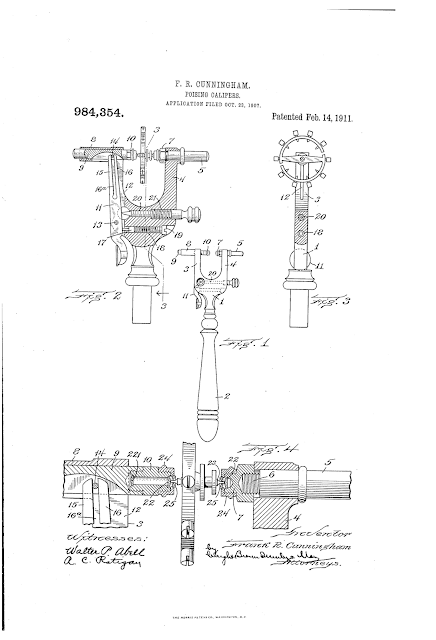

Of the accompanying cliavings,-Figiii’e 1 represents an elevation ot a tool embodying the principles of my invention. Fig. Q represents a sectional view of the same on an enlarged scale. Fig. 3 represents a crosssection on .line 3—3 ot Fig. 2. lF it represents an enlarged section through the bearings, illustrating in detail the construction thereof.

The same reference characters indicate the same parts in all the figures.

The instrument consists ot’ a frame 1 carried by a handle 2, and having arms 3 and 4l. These arms are separated somewhat and are absolutely rigid. having no relative movement of approach or recession whatever. In one of the arms, as. 4, is set a pin 5 passing entirely through the arm and having a threaded shank G on the inner side of the arm, to which shank is attached a stationary bearing 7. On the other arm is a tubular guide 8 in which is slidably contained a bar 9 carrying a movable bearing l0. The pin 5, bar 9 and bearings are all in line, and the movable bearing reciprocates on this line toward and from the fixed bearing. For so moving the bearing 10, l. provide an actuating lever 11 contained in a slot 12 in the arm 3, and pivoted upon a pin 18 in the caliper loody at the base of this arm. Connec- Speeieaton of Letters Patent.

Patented Feb. 14, 1911.

serial No. 398,760.

tion is made between the lever and slide 9 by means ota pin t-‘lon the latter, and resilient lingers l5 ,ttt on the end ot’ the lever. These fingers are separated by a slot 1G which, when the lever is free of the pin. is ot less width than the diameter et’ the latter. Consequently the insertion of the pin into this slot spreads the lingers apart somewhat, causing` them to embrace the pin and thus absolutely preventing any lost motion between they level.’ and slide.

ln the base ol” the caliper Yframe is formed a passage containing a plunger 17, a spring 1S pressing said plunger outward, and an abutment screw itt). The plunger bears against the lever 1l on the opposite side of its pivot ‘from the slide 9. and so tends to press the slide and the bearing carried thereby toward the fixed bearing 7. Threaded into the aliper -trame is a screw Q() which projects toward the lever 11 on the, opposite side o’t` the pivotV ,13 trom the sjn’ing-pressed plunger. This screw is in the path of the lever and serves as a stop to limit the approach ot the niovable bearing toward the fixed one. By turning the outer end of the screw, its position can be altered, and the distance between the bearings when brought to restv` adjusted. ly means o’tE this adjustment, the bearings can be separated so as to remove all t’rietion-producing pressure from the ends ot the sta tll held between them, and at the same time retain the stati without looseness. AV spring Q1 bears against the stop screw and holds one side ot its threads in engagement with the eomplemental thread oi the socket, wherein it is contained, thereby taking up any looseness which there may be. This stop is designed to limit the approach ot the mo vable bearing 10 toward the tixed one, and to adjust the space between the bearings so exactly that the statil ot’ a wheel may be held between them without friction-causing pressure on its end, and also without too great looseness. The actuating lever causes the movable bearing to be advanced toward and withdrawn from the fixed bearing rapidly so that wheels may be inserted and removed with the greatest convenience, while the adjustable stop serves to tit’y the bearings tor staffs ot all sizes. The connection between the lever and slide consisting ot the pin 14 in the slot 16, allows the slide to move. rectilinearly, while the resilience of the spring fingers causes them to bear with the same pressure on each side of the pin and so eliminate lost motion. This result, elimination of looseness, is further forwarded by the spring-pressed plluiger 1T’, which normally presses the b arings together’ and tends to hold the lever in contact with the stop 20.

One of the important innirovements of my invention is the constuction of the bearings. These are provided with jewels against one of which the end of the statt bears, while the other surrounds the staff and holds it against sidewise movement, and are separable so that they may be easily cleaned and polished. The bearing ‘T consists of a main holder which has a base in the form of a nut, and is screwed upon the threaded end of the pin 5. n its tip this holder provided with a. socket in which is set an end-thrust bearing jewel 22 which has preferably a plane, or at least unrecessed, surface against. which the end of the balance wheel statt is adapted to bear. The holder’ 7 is threaded externallj7 and receives a screw cap Q4 constituting the holder for the second jewel 25 of the bearing. This jewel is annular, having a central hole through which projects the reduced pivot of the staff. The movable bearing l0 is essentially similar, consisting of the main holder to which the numeral l0 is applied, carrying the end bearing ewel 2Q, and being threaded to receive the cap 24k which holds the annular bearing jewel It differs from the other bearing, however. in this, that the main holder l0 is symmetrical withA respect to its ends, being threaded into a socket in the slide 9, and capable of being turned end for end. In its opposite end it carries a jewel 221 similar to the jewel 22, which can be put into use by simply reversing the holder l0 in the socket and applying the cap 2st to the other end. rlhis capability doubles the life of the bearing, permitting replacement of a defaced or unsuitable jewel without necessitating’ delay for repairs.

In using the instrument for poising a balance wheel, the staff of the latter is first set in the bearings and adjusted so that there will be no end shakeor friction. The weights of the screws which are set into the rim of the balance are then varied in the usual way until the center of gravity is eX- aetly in the axis of the staff. In order to determine if the wheel is perfectly poised, it is set. into rotation b v vibrating the ltool through rubbing upon a portion of it, thetool being held against the edge of a bench. T he rubbing is done by an instrument which has suflicieut friction to set the tool vibrating, thus causing the balance to be rotated. lf it is perfectly poised. it will continue rotating as long as the rubbing is kept up, but if not so poised, it will of course come to rest with its heaviest portion downward. It is for the purpose of it’urnishing a convenient member to take the rubbing without injury to the apparatus as a whole that l lprovide the detachable projecting pin After considerable use, the part of the apparatus which is rubbed upon will become worn a ‘ay, and if no provision were made for replacing the worn part, it would become unfit for use. lVhen, however, the pin 5 is worn away, no harm is done, because a new pin can readily be substituted.

l claim:-

1. fr poising caliper, comprising a pair of rigid arms, opposed bearings mounted on said arms, one of which bearings is movable in a guide on its respective arm, an actuating lever for the movable bearing having spring lingers. and a pin on said movable bearing grasped between said lingers, whereby the bearing is enabled to move rectilinearly and lost motion is prevented.

poising caliper, comprising a pair of rigid arms, opposed bearings mounted on said arms, one of which bearings is movable in a guide on its respective arm, an actuating lever for the movable bearing pivoted to the body of the caliper, a spring-pressed plunger bearing on said lever on one side of its pivot tending to move it so as to press the movable bearing toward the other, an adjustable stop threaded into the caliper bodjY on the other side of the lever pivot from said spring-pressed plunger so as to limit the approach of the lever and movable bearing toward the other, and a spring arranged to press the threads of said stop in one direction against its complemental engaging threads to take up looseness between them.

3. A poising caliper, including a frame, a socket supported thereby, a reversible holder adapted to have either end detachably inserted and held in said socket, end-thrust bearing jewels set in both ends of said holder, a. cap detachably fastened on the outer end of the holder, and an annular lateral-bearing jewel set in said cap.

Lt. A, poising caliper comprising av frame having an intermediate space to receive a balance wheel, a bearing rigidly secured to said frame at one side of said space for one of the pivots of the balance statt, a bearing for the other pivot of said staff mounted at the other side of said space, with provisions for moving toward and from said fixed bearing. a` lever pivoted to the frame engaging said movable bearing and having a finger piece by which it may be engaged to retract the bearing, a spring-pressed pin mounted in said frame. and bearing` on said lever at one side of the pivot thereof to urge the movable hearing toward the fixed bearing, and an adjustable stop threaded into the frame in the path of said lever on the opposite side of the the movable bearing toward the fixed bezu’- secured to Suid ring approxmmtely conxiully ing. therewith.

5. A poising Caliper comprising u. frame ll CSHOHX WhCl’COf I 111W@ IIHXCCl my 5 and Separated bem-ings for the pivots 0f a s1g1mt1lre,1n presence of two Wltnesses.

b alance Staff Set upon said frame and rela- FRANK R CUNNINGHBL tlvely movable together and apart for admitpivot thereof for limiting the movement of 1 holder, und :111 annular lateral bearing jewel ting and holding such pivots, each bearing lftnesses: lneludmg a holder having an end thrust; ARTHUR H. BROWN,

10 jewel, :L ring detaohably threaded upon said l. NV. lmzzlc’r’rl.