Patented May 18, 1909.

UNITED STATES PATENT OFFICE

FRANK R. CUNNINGHAM, OF MEDFORD, MASSACHUSETTS,

ASSIGNOR TO KENDRICK & DAVIS, OF LEBANON, NEW HAMPSHIRE, A FIRM.

WATCH-HAND REMOVER.

Specification of Letters Patent.

Patented May 18, 1909.

To all whom fit may concern:

Be it known that I, FRANK R. CUNNINGHAM, of Medford, in the county of Middlesex and State of Massachusetts, have invented certain new and useful Improvements in Watch-Hand Removers, of which the following is a specification.

This invention relates to tools for removing the hands of watches and clocks from the arbors on which they are placed, and has for its object to improve tools of this character by providing a centering and retaining device for more readily locating the hand removing jaws and for preventing loss of the hands after their removal.

The invention therefore consists in a tool of this character having a yielding hand retainer and jaw-centering device associated in combination with the other operative parts whose function is to pull the hand from its arbor.

The invention also consists in improved details of construction of the tool which enable the hand-retainer and jaw-centerer to be applied in connection with the other parts of the tool.

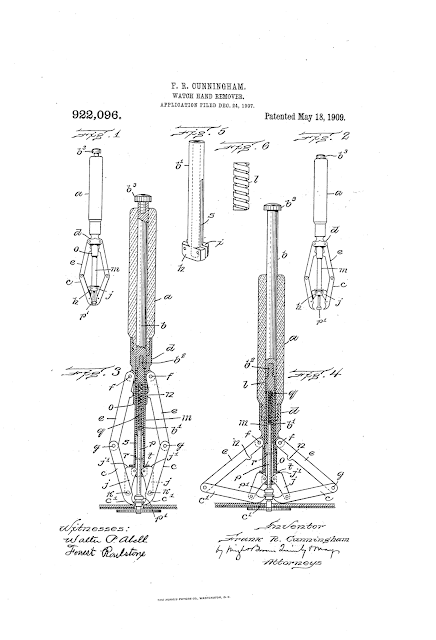

Of the accompanying drawings, Figure 1 represents an elevation of the tool in its normal inoperative condition. Fig. 2 represents a similar view, showing the removing jaws separated, preparatory to being inserted beneath the hub of a watch-hand. Fig. 3 represents a sectional elevation on an enlarged scale, showing the tool engaged with a watch hand preparatory to drawing the same from its arbor. Fig. 4 represents a sectional elevation, showing the position of the parts of the tool at the end ‘of the hand removing operation.Figs. 5 and 6 represent details of parts of the tool.

The same reference characters indicate the same parts in all the gears.

The tool consists of a handle and operating rod, hand-removing levers, and associated parts. The operating rod by passes through the handle and both the rod and handle are movable with respect to each other. To the lower end of the handle is removably attached by screwing, a hub or head, which has slots in its opposite sides wherein enter links, which are united to the hub by pivots These links also pass into slots in the upper or outer end links into line portions of the levers c and are pivotally attached thereto by pins g.

For purposes of construction and convenience in assembling, the operating rod is made in two parts, of which the lower part is represented by b and is united with the upper part by a screw-threaded stem b2. The lower end of the rod section b has lugs between, which enter, and are held by pins, links. The lower ends of the latter enter slots in the levers c in which they are held by pins 7c. The lower ends of the hand removing levers below the pins are thinned so as to provide sharp-edged jaws which can enter between the upper surface of the dial of a watch and the hand.

On their adjacent sides above the jaws, the levers are concave so as to provide room for the eye or hub of the hand, while on their outer faces the levers are convex, providing shifting fulcrum points upon which the levers bear when pressure is applied to their upper ends.

When the tool is not in use and all the parts are in equilibrium, it has the appearance shown in Fig. 1. This position of the parts is produced by a spring Z interposed between a shoulder at the lower end of the upper part of the operating rod b, and a sleeve, which surrounds the lower section t of the operating rod. This spring forces the sleeve downward and causes it to exert its pressure on the links y outside of their pivots. Thereby, the swinging ends of the links are impelled toward one another, drawing the jaws together and at the same time drawing the pivotal connections g inward, raising the handle a and tending to draw the levers c. This tendency is resisted, however, by protuberances n on the links which bear against a sleeve o projecting downward from the head d. Thus the links and hand-removing levers are always inclined slightly outward.

In using the tool, the handle is grasped between the thumbvand middle finger, and held vertically over a watch which is placed face upward. The operating rod is then depressed, it having angler-piece t3 which enables the forefinger to actuate it. This pressure of the rod acting downwardly on the link y causes the jaws to be separated sufficiently to impress the hand arbor of the watch. Then the pressure is removed from the rods, the jaws are drawn by the spring Z into the space between the watch-hand and dial against the arbor. The handle a is then pressed down, which imparts a downward pressure through the links e to the outer ends of the levers c. The latter are then caused to turn about the curved fulcrum surfaces c, raising the jaws with a powerful leverage, and prying the ends from the arbor.

The point of tangency at which the curved surface on the outer end of each lever bears on the adjacent supporting surface of the watch or’clock, constitutes a shifting fulcrum about which the lever turns in removing the watch hand. That portion of the lever extending between its extreme end and the shifting fulcrum point is the short arm of the lever, and it is shaped somewhat as a jaw. As the action of these short lever arms in removing a hand is a prying action, I term the end portions of the levers prying jaws or prying arms.

In tools of this character hitherto used, great difficulty has been experienced in preventing loss of the hands after their removal from their arbors, As after removal from its arbor va hand is only supported on the jaws at one end,its projecting end tends to overbalance it and cause it to drop from the jaws always causing inconvenience and sometimes loss. By my invention, I have provided a retainer which presses against a hand held by the jaws and continues to maintain it in contact with the jaws until it can be deposited where required. rI`his retainer consists of a baror rod p having a head on its lower end, and partly contained within a central chamber of the lower operating rod section b. Between the end of the bar and the end of the chamber is a spring g tending to press the head of the retainer against the jaws or against a hand supported upon them. Total ej ectment of the retainer bar when the jaws are separated is prevented by a pin r passing through the bar into slots s in each side of the operating rod, said pin being prevented from passing out oi’ the ends of said slots by the links j. In order to permit the presence of the presser rod, these links are separated from-one another and pivoted by separate pins, but they are not far enough apart to allow the detent pin r to pass between them. In order to apply the pressure of the operating spring Z to the links at some distance from the pivots of the latter, and thereby obtain sufficient leverage for the purposes required, the links are widened at their upper ends to provide curved protuberant corners y, and between the lower end of the sleeve m and the upper ends of the links is an annular disk t which has its bearing on the links a considerable distance beyond the outer circumference of the sleeve.

I claim:

1. A tool for removing the hands, a handle, an operating rod movable longitudinally through the same, hand-removing levers having cooperating prying arms, connections from said levers to said handle and rod, and a retainer cooperating with said arms for holding the hand alter removal from the arbor.

2. A watch-hand-removing tool, consisting ol’ cooperating levers having prying jaws adapted to be inserted between the hand and dial of a watch, a handle to which said levers are linked and by which they are operated to pry the hand from its arbor, and a yielding presser arranged to bear on said jaws and hold the hand upon the same.

3. A watch-hand-removing tool, consisting of cooperating levers having prying jaws adapted to be inserted between the hand and dial of a watch, a handle to which said levers are linked and by which they are operated to pry the hand from its arbor, and a yielding presser arrangedly between said levers and above said jaws to bear against the latter and hold the hand thereon after its removal from the arbor.

4. A tool for removing the hands ol watches and the like, comprising in combination, a handle, an operating rod movable longitudinally through the same, hand-removing levers having cooperating prying arms, connections from said levers to said handle and rod, and a retainer within said rod cooperating with said arms for holding the hands after removal from the arbor.

5. A tool for removing the hands of watches and the like, comprising in combination, a handle, an operating rod movable longitudinally through the same, hand-removing /levers having cooperating prying arms, connections from said levers to said handle and rod, and a retainer bar contained within said rod and yieldingly impelled outward toward said arms to hold a hand thereon after removal of the hand from the arbor.

6. A tool for removing the hands of Watches and the like, ‘comprising in combination, a handle, an operating removable longitudinally through the same, hand-removing levers having prying jaws, links connecting said levers to said handle’V and operating rod respectively, and a spring-pressed sleeve surrounding said rod and Acting upon the rod-connected links to draw the jaws together.

7. A tool for removing the hands of j watches and the like, comprising in combination, a handle, an operating rod movable longitudinally through the same, hand-removing levers having prying jaws, links pivotally connecting said levers to said handle, a Y y acting upon the last-named links outside ol’ their pivots with tendency to bring and hold the jaw ends of the levers together.

8. A watch-hand removing tool comprising separable prying jaws adapted to be inserted between the hand and dial ol a watch or clock on opposite sides of the hand arbor, a centering member between said jaws engageable yieldingly with the end of the arbor, and when so engaged serving to locate the jaws correctly with respect to the arbor and hand, and an operating handle to which said jaws are jointed.

9. A watch-hand removing tool comprising levers having their adjacent ends thinned so as to be capable of entering between the hand and dial of a watch or clock and having fulcrum bearings on their outer sides, a handle and a rod relatively movable axially, links pivoted near opposite ends of said levers and connected respectively to said handle and rod, and a hand-retainer between said levers yieldingly impelled to bear on the thinned ends of the latter or on a hand held thereby.the levers, and links pivoted to the levers near their thinned ends and to the rod on opposite sides of said plunger.

11. A tool for removing the hands of watches and the like, comprising in combination, a handle, an operating rod movable longitudinally through the same, hand-removing levers having linked connection with said handle, links joining said levers also to said operating rod, a sleeve surrounding the latter, a shoulder on the rod, and a spring surrounding the rod and bearing against said shoulder and sleeve, tending to press the latter toward said links and thereby swing their moving ends toward one another and retract the handle.

12.. A tool for removing the hands of watches and the like, comprising in combination, a handle, an operating rod movable longitudinally through the same, hand-removing levers having linked connection with said handle, links joining said levers also to said operating rod, a sleeve surrounding the latter, a shoulder on the rod, a spring surrounding the rod and bearing against said shoulder and sleeve, and a ring interposed between the sleeve and links to apply the pressure oi’ the spring on the latter at points outside of their connections with the rod.

In testimony whereof I have affixed my signature