| Publication number | US798000 A |

| Publication type | Grant |

| Publication date | Aug 22, 1905 |

| Filing date | Mar 17, 1905 |

| Priority date | Mar 17, 1905 |

| Inventors | Lester J Williams |

| Original Assignee | Kendrick And Davis |

| Classifications (1) | |

DESCRIPTION (OCR text may contain errors)

WATCH ROLLER REMOVER.

APPLICATION FILED MAR. 17, 1905.

UNTTED STATES PATENT OFFICE

LESTER J. WILLIAMS, OF LEBANON, NEW HAMPSHIRE, ASSIGNOR TO KENDRICK AND DAVIS, OF LEBANON, NEW HAMPSHIRE, A FIRM.

WATCH-ROLLER REMOVER.

Specification of Letters Patent.

Patented Aug. 22, 1905.

Application filed March 1’7, 1905. Serial No. 250,609.

To whom it may concern:

Be it known that I, LESTER J. WILLIAMs, of Lebanon, in the county of Grafton and State of New Hampshire, have invented certain new and useful improvements in Watch-Roller Removers, of which the following is a specification.

This invention relates to tools used by watchmakers for removing from the staff of a watch-balance the disk known as the roller, said disk having a frictional fit upon the balance-staff.

The invention has for its object to provide a simple, inexpensive, and effective tool of this character which may be conveniently adapted for use with watch-balance staffs and rollers of different sizes.

The invention consists in the improvements which I will now proceed to describe and claim.

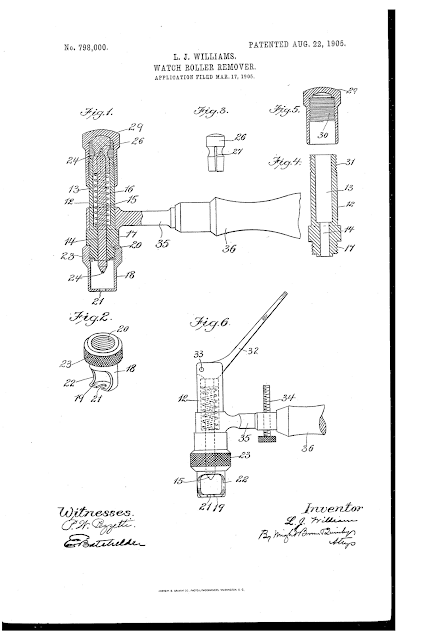

Of the accompanying drawings, forming a part of this specification, Figure 1 represents a sectional view of a roller-remover embodying my invention. Fig. 2 represents a perspective view of the part of the tool which includes the roller-seat. Fig. 3 represents a side elevation of the plunger-holder shown in section in Fig. 1. Figs. 4: and 5 represent sectional views of the barrel and screw-cap, respectively. Fig. 6 represents a side view showing a lever for projecting the plunger.

The same reference characters indicate the same parts in all the figures.

In the drawings, 12 represents a body or barrel, which is preferably cylindrical and is provided with a longitudinal bore having a larger portion 13 and a smaller portion 14, the latter serving as a guide for the plunger 15, which is pressed against the end of the balance-staff to force the same from the roller is preferably tubular and is provided with means such as an internal screw-thread 20, adapted to engage the external thread 17, for detaching and connecting the extension with the barrel. The seat 19 is preferably a head formed at the outer end of the extension 18 and is provided with a slot 21 to receive the balance-staff, the extension being cut away at one side to form an opening 22, which permits the application of the roller to the upper side of the seat 19. In practice each tool will be provided with a plurality of extensions 18, each formed for use with a different size of staff or roller, the several sections being adapted to be used interchangeably. The up per portion of the extension is preferably provided with a knurled or milled enlargement 23, constituting a handle, whereby the extension may be conveniently rotated to apply and remove it.

As shown in Fig. 1, the plunger 15 is double ended, that is to say, it has in each end a cavity 24:, adapted to engage the conical end of a balance-staff, one of said cavities being smaller than the other, so that the two are adapted for use with balance-staffs of different sizes. The plunger is reversible, so that either of its ends may be the acting end. 26 represents a holder which is adapted to be detachably engaged with the upper or inner end of the plunger, said holder being movable with the plunger in the enlarged portion 13 of the barrel-bore. The holder 26 is preferably a collar having a socket formed to receive one of the end portions of the plunger, the Walls of said socket being subdivided by longitudinal slots 27, Fig. 3, into spring-arms which normally spring inwardly to contract the socket. When the plunger is forced into the socket, it springs the arms outwardly and causes them to frictionally engage the plunger, so that the holder and the plunger are adapted to be moved together as one part. The holder 26 has a sliding it in the enlarged portion of the bore of the barrel. The spring 16 bears upon the inner end of the holder 26 and tends to force the latter and the plunger upwardly, thus normally retracting the plunger.

The plunger may be projected by any suitable projecting device. In Figs. 1 and 5 I have shown as the projecting device a cap 29, having an internal screw-thread 30 adapted to engage an external thread 31, formed on the upper portion of the barrel 12. The head of the cap 29 bears on the holder 26, the latter being pressed against the cap-head by the spring 16. When the cap is rotated in the direction required to feed it downwardly upon the barrel, it forces the holder and plunger’in the same direction, thus projecting the plunger and causing it to force the balance-staff from the roller. When the cap is rotated in the opposite direction, the spring causes the holder and plunger to move outwardly with the cap.

In Fig. 6 the projecting device is shown as a lever 32, pivoted at 33 to the barrel and having a projection which may bear upon a holder 26, like that shown in Fig. l, or directly upon the upper end of the plunger in case the latter is not made reversible. 34 represents an adjustable stop-screw to limit the downward movement of the lever which causes the projection of the plunger. 35 represents a shank suitably engaged with the barrel and provided with a handle 36. The stop-screw 34 is engaged with a tapped orifice formed in the said shank.

– I do not limit myself to the details of construction above described and may variously modify the same without departing from the rel, a holder adapted to detachably engage either end of the barrel, said holder being movable with the plunger in the barrel, and means for moving the holder to project and retract the plunger.

2. A tool of the character stated,comprising a barrel or body, a roller-seat secured thereto, a double-ended plunger movable in the barrel, a plunger-holder movable in the barrel and having a split socket adapted to automatically engage either end of the plunger, and means for moving the holder to project and retract the plunger.

3. A tool of the character stated,comprising a barrel or body, a roller-seat secured thereto, a double-ended plunger movable in the barrel, a holder adapted to detachably engage either end of the barrel, said holder being movable with the plunger in the barrel, an internally-threaded cap engaged with an external thread on the barrel and bearing on the holder, and a spring which presses the holder against the cap.

In testimony whereof I have affixed my signature in presence of two witnesses.

LESTER J. WILLIAMS.

Witnesses:

CLARENCE E. HIBBARD, A. J. RICHARDSON, Jr.