| Publication number | US992206 A |

| Publication type | Grant |

| Publication date | May 16, 1911 |

| Filing date | Apr 2, 1908 |

| Priority date | Apr 2, 1908 |

| Inventors | Frank B Kendrick |

| Original Assignee | Kendrick & Davis Company |

| Classifications (1) | |

| External Links: USPTO, USPTO Assignment, Espacenet | |

DESCRIPTION (OCR text may contain errors)

STAKING TOOL.

Application FILED 23.2, 190s.

992,206. Patented May 16, 1911.

ref- 2 ‘UNITED STATES PATENT OFFICE.

FRANK B. KENDRICK, OF LEBANON, NEW HAMPSHIRE, ASSIGNOR, BY MESNE ASSIGNMENTS, ’10 KEN DRICK & DAVIS COMPANY, OF LEBANON, NEW HAMPSHIRE, A CORPORATION OF NEW HAMPSHIRE.

STAKING-TOOL. l

Specification of Letters Patent.

Patented May 16, 1911.

T o all whom ‘it may concern:

Be it known that I, FRANK B. KENDRICK, of Lebanon, in the county of Grafton and State of New ‘Hampshire have invented certain new and useful Improvements in Staking-Tools, of which ‘the following is a specification.

This invention relates to staking tools and has for its object to provide a novel means for binding the die in position so that any desired one of the apertures which receive the stumps may be retained in proper’position under the punch guide. It has hitherto been the general custom to bind the die in place by means ot’ a cam on a shaft extending through the base of the die from front to rear, the cam being contained 1n a slot in a vertical pin which passes through the base of the tool and is attached to or engaged with the die. The shaft carrying such cam or its equivalent and eccentric is provided with an external hand-wheel by which it may be turned to bindV the die by drawing it down upon the top of the base, and to release the same.

By the present invention I eliminate the cam, the shaft and the hand-wheel, securing the result of frictionally locking the `die by providing a nut located Within the base, which nut draws directly down upon the bolt or pin and so presses the die against its seat. By this arrangement the die-locking means is contained Within the base and protected from being accidentally displaced. This arrangement also enables the tool to be made without unnecessary external projections, and renders it more compact, besides diminishing the liability of the tool being caught or struck by external moving objects.

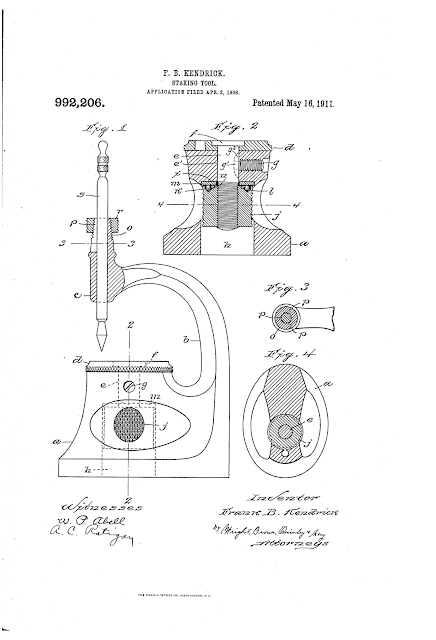

Of the accompanying drawings,-Figure 1 represents a side elevation, partially in section, of a staking tool constructed 1n accordance with this invention. Fig. 2 represents a section on line 2-2 of Fig. l. Fig. 3 represents a section on line 3 3 of Fig. 1. Fig. 4 represents a section, on a smaller scale, on line 4-4 of Fig. 2.

The same reference characters indicate the same parts in all the figures.

The tool comprises the usual base a having a neck b and a head c forming a guide for a punch or centering tool. The base has a flat top on which rests the circular die (l having a series of apertures of graded sizes.

A pin or bolt c passes through the base and has a head for engaging the die and acting when depressed to bind the latter against its seat on the base. There is a passage through which the bolt extends, this passage being enlarged at the bottom of the tool to form a recess or chamber it which is bounded by a flat annular shoulder z’ extending from the walls of the passage outward to the walls of the recess.

The end portion of the bolt which extends into the recess is threaded and has screwed upon it a nut y’, the latter, when turned up on the thread, serving to press indirectly upon the shoulder z’, and by its reaction, draw the bolt and die downward, pressing and binding the latter upon the top of the base so that it cannot be turned. In order to eliminate friction of the nut upon the shoulder z’, there is interposed a series of anti-friction balls 7c, these balls being con-l tained in a groove Z in the nut, and bearing against a steel washer m on the under side of the shoulder. The balls are retained in the groove by an annular retainer in which allows the nut to be entirely removed and’ inverted if occasion requires, without danger of the balls spilling out.

The nut is wholly contained within the recess L, and in order to make it accessible so that it can be rotated, the sides of the tool are recessed so as to expose the sides of the nut. This enables the user of the tool to grasp the nut between his thumb and foreiinger and turn the same. As the nut is thus wholly contained within the periphery of the base, it affords no projecting points liable to be caught or struck accidentally, so that danger of loosening the die from this cause is avoided. It also permits the elimination of the usual external hand-wheel, which in the old type of staking tool projects considerably and affords an opportunity for the tool to be accidentally displaced and knocked about.

It is necessary to prevent displacement of the die while it is being clamped by the nut, and for that purpose I provide an element in the nature or’ a key which holds the bolt from rotation, and limits its motion to an endwise displacement. Such key element is conveniently a screw g set into the side of the base in a tapped hole which intersects the passage e’, and having a reduced end g projecting into a longitudinal groove or keyway g2 in the side of the bolt. Thus the bolt, while being permitted to move freely endwise, is prevented from turning and displacing the die when the nut j is turned. IThe engagement between the bolt and die is such that the latter may turn freely when released by loosening of the nut.

Another feature of improvement of the .staking tool is the adjustable friction by which the punch or centering tool may be retained in the head at the same distance above the die. When the head is made with an aperture sufficiently large for the tool to slide loosely through it, the latter must either be held by the workman while the die is being adjusted, or where it is necessary to use two hands in adjusting and clamping the die, the centering tool must be entirely removed and laid down to permit of this action. I have devised a scheme by which the tool may be allowed to remain in the head, and yet be held automatically high enough above the die to enable the latter to be turned, and the workman to use one hand for holding the die stationary, while the other is used to clamp it. This result is accomplished by providing the head c with an extension o which is divided by longitudinal slots p into semi-detached spring fingers. The extension constitutes a split externally tapered sleeve which is threaded on the outside and receives a clamping nut i”. This nut may be adjusted to give any amount of compression desired to the parts of the sleeve, and ordinarily is fixed so that the centering tool s or other tool which may be held in the head, can be moved up’and down easily by a slight pressure, but will be held when the workman leaves it alone.

I claim l.

A staking tool comprising a base having a passage extending from its bottom upwardly and a second passage of smaller diameter extending downwardly from its top and opening into the first passage, and having also a shoulder at the top of the first passage, a head rising from and overhanging the base, a die plate mounted on the top of the base, a threaded bolt engaged with the die, fitting the second passage and extending into the first passage, and a nut of substantially the same diameter as the first passage contained therein, threaded upon the bolt and bearing against the shoulder, the base having recesses in its opposite sides intersecting the first passage and exposing the sides of the nut.

2. A staking tool comprising a base, a head overhanging the base, a die resting on the top of the base, a locking bolt with which the die has a rotative engagement, passing from the die into the interior of the base, the latter having a recess opening from its bottom, at the top of which recess is a shoulder, a nut threaded upon the bolt and arranged to bear against such shoulder to clamp the die on the base, and a key member extending into a longitudinal groove in the bolt and engaged with the base to prevent rotation of the bolt.

3. A staking tool comprising a frame having a base with a passage through it, a recess in its lower portion and al flat shoulder between the walls of the passage and recess, a die supported on said base, a threaded bolt engaged with said die and extending through said passage into said recess, a nut having a groove screwed upon said bolt, a series of balls in such groove adapted to bear upon said shoulder to transmit binding pressure to the die, and a ball retainer attached to the nut holding the balls in the groove when the nut is removed.

4. A staking tool comprising a frame having a base with a passage through it, a recess in its lower portion and a flat shoulder between the walls of the passage and recess, a die supported on said base, a threaded bolt engaged with said die and extending through said passage into said recess, a nut screwed upon said bolt, having a groove in its face next to said shoulder and an annular shoulder rising near one of the edges of such groove, a series of balls contained in the groove, and a ring frictionally held by said shoulderl so as to project at one edge partially over the groove and the balls therein, to retain the balls when the nut is loosened.

In testimony whereof I have affixed my signature, in presence of two witnesses.

FRANK B. KENDRICK.

Witnesses:

ARTHUR H. BROWN, P. W. PEZZETTI Copies of this patent may be obtained for five cents each, by addressing the Commissioner of Patents, Washington, D. C.

| Cooperative Classification | G04D3/04 |

.png)